Understanding Bloodbags

Definition and Purpose of Bloodbags

What is a Bloodbag?

Blood bags are tools in healthcare for gathering and preserving blood for transfusions while keeping it safe and in good condition until needed.

The Role of Blood bags in Medical Settings

Blood bags are essential in healthcare settings as they create a space for collecting and storing blood safely. Hospitals and clinics rely heavily upon them to enable blood transfusions while maintaining the purity of the blood until it is needed.

Types of Bloodbags

Single Bloodbags

Blood bags made for storing and collecting blood usually have one section to hold the gathered blood, and they are commonly used when whole blood transfusions are needed.

Double and Triple Bloodbags

Double and triple blood bags represent systems that enable the division of diverse blood elements, like plasma, red blood cells, and platelets. These specialized bags feature sections that empower medical professionals to segregate and preserve different components based on specific medical requirements.

Importance of Bloodbag Safety Standards

Ensuring Patient Safety

It’s really important to follow safety guidelines when it comes to handling blood bags to keep patients safe during transfusions. This helps prevent any contamination and keeps the blood sterile during storage and transfer processes, reducing the chances of infections or negative reactions during transfusions.

Maintaining Blood Integrity

Ensuring the quality of preserved blood is crucial for its efficacy in therapies, as well-designed blood bags help maintain the original properties of stored blood until it is required for transfusion.

Regulatory Framework for Bloodbag Safety

International Standards and Guidelines

Overview of ISO Standards for Bloodbags

The ISO offers guidelines that outline the manufacturing process and quality control measures for blood bags to ensure they meet global safety standards effectively.

Role of WHO in Bloodbag Safety Regulations

The World Health Organization (WHO) is crucial in setting rules that regulate the management and utilization of blood products on a global scale. The guidelines from WHO aid in standardizing procedures, among nations to guarantee uniform safety protocols.

National Regulations and Compliance

FDA Guidelines for Bloodbag Manufacturing

In the US, the Food and Drug Administration (FDA) establishes regulations for producing medical equipment such as blood bags. These regulations include a range of aspects, from choosing materials to implementing quality checks to guarantee the safety of the products.

EU Directives on Medical Devices

Europe’s guidelines for devices, detail the necessary steps manufacturers must take to sell their products in EU countries. The directives guarantee that all medical equipment, like blood bags, meet safety criteria.

Quality Control Measures in Bloodbag Manufacturing

Material Selection and Testing

Types of Materials Used in Bloodbag Production

Blood bags are usually crafted from chloride (commonly known as PVC) due to their strength and ability to work well with human tissues, ensuring that the materials undergo thorough testing to prevent any negative reactions with the preserved blood.

Testing Procedures for Material Durability and Compatibility

Manufacturers perform evaluations on materials to determine their strength in different situations, while compatibility assessments guarantee that materials don’t release any harmful substances into the blood being stored or change their characteristics.

Sterilization Processes

Methods of Sterilization in Bloodbag Production

Various techniques are used to ensure blood bags are sterile during production, such as gamma irradiation and ethylene oxide sterilization, which help remove any microbial contamination from the manufacturing process.

Ensuring Sterility Throughout the Supply Chain

To uphold cleanliness across the supply chain process, companies follow stringent guidelines when packaging, transporting, and storing products. This guarantees that each bag stays free from contamination until it arrives at its location.

Manufacturers of analyzers create specialized medical devices used to measure the levels of electrolytes in biological samples, such as blood or serum.

Reliability in the Use of Bloodbags

Proper Storage Conditions for Bloodbags

It is important to maintain the storage conditions to keep blood bags containing crucial blood components safe and effective. To store blood bags correctly; whole blood and red blood cells should be kept between 1°C to 6°C. Platelets need to be stored at room temperature with movement. Frozen plasma is usually stored below 18°C. The storage conditions mentioned are crucial for maintaining the effectiveness and functionality of the blood components until they are needed for transfusions.

Handling Procedures to Prevent Contamination

Procedures for managing blood bags are vital in preventing contamination risks. Healthcare workers need to follow cleanliness practices when handling blood bags from collection to transfusion stage by using sterilized tools and wearing suitable protective attire while adhering to established protocols for bag handling. Moreover, maintaining sterility is crucial during transportation and storage by minimizing exposure to contaminants.

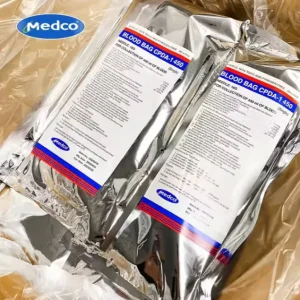

Medco’s Commitment to Quality and Reliability

Medco is a medical devices provider based in China, places a strong emphasis on ensuring the quality and dependability of its product range in the market sector it has served for over 18 years now. Medco is known for its expertise in the production and promotion of diagnostic instruments, disposable medical supplies and laboratory supplies.

Medco demonstrates its dedication to quality through its compliance with international certifications like CE0123, ISO13485 certificates, and FDA approval, emphasizing the importance of stringent quality control measures in all operations to ensure that each product undergoes meticulous testing before delivery, guaranteeing the adherence to stringent safety regulations for medical purposes in all their offerings.

Medco stays ahead in addressing healthcare challenges by enhancing its methods and diversifying its product range to meet the demands of the market effectively.